Thank you Holden, but Joe was right

Joe Hockey made the right call.

I say this keeping in mind that two of the most talented engineers I know cut their teeth at Holden.

One, a long-time friend from school days, is now a professional inventor (as well as a qualified patent attorney) in the process of commercialising an array of technologies. I am just awestruck with wonder at the kind of things he is able to design and then produce. He is capable of bringing together an array of technological concepts to solve problems as different as a carpet that cleans itself to an iPhone app plus gyrometer to improve your golf swing.

Did he learn all this stuff at Holden?

Nope. But first Ford and then Holden, gave him his start, ensuring his degree in engineering could be put to immediate use. Which then allowed him to build confidence and skills. At Holden, one of his contributions was modelling the air flow fed into the V6 engine which led to reconfiguration of its original design to reduce friction, which then allows the engine to become more efficient. Not many companies can provide engineers with such an array of engineering challenges to solve, to build their skills and knowledge.

The other engineer decided to quit Holden after many years because he wanted to make a practical contribution to countering global warming (something I’m still working on with my school friend). He now advises an incredible array of businesses – from mining companies to the chemicals industry to power generators – on how they can save energy. Again, I’m often amazed at what he can conceptualise and then implement.

A few weeks ago I was chatting to a staff member of metal fabricator IXL about the company's recent win to supply framing for Australia’s largest solar power installation. He explained that, thanks to the extremely precise tolerances learnt through working for Toyota, the solar project is something the company's team is more than capable of handling.

I’ve heard university engineering professors complain that while they might be able to come up with all sorts of wonderful ideas in their research, it wouldn’t be possible without an industrial base in the country to supply jobs for their students which ultimately kept them employed. It was a bit like the chicken or the egg problem in their eyes. You want high quality research and educational facilities for the country to develop new and innovative industries and jobs? Sure, but you need some existing employers of engineers around first before anyone will pursue an engineering education.

Clearly there are very valuable skills and capabilities that the automotive sector and manufacturing more generally help to foster.

Learning and research without application is often a fast route to an esoteric dead end.

Yet, at the same time I have also been told of how talented engineers have been handcuffed by head offices in Detroit and Tokyo. For a motor vehicle operation to be viable it must produce for a global market, not just an Australian one. Economies of scale and scope are too important. The reality is that Ford, Toyota, General Motors and Mitsubishi have had global strategies which just haven’t included Australia as a significant part.

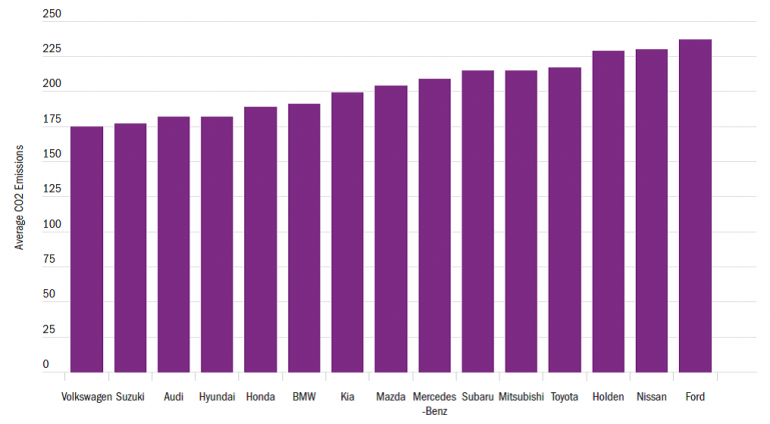

This has constrained Australian operations from essentially trying to build their own future that would ensure sustainability over the longer term. Australian operations aren’t free to develop their own export markets essential to develop economies of scale. They also haven’t been free to develop genuinely fuel efficient and leading edge vehicles, viable in a world of high oil prices and stringent emission standards. The chart below illustrates in terms of average vehicle CO2 emissions (and therefore fuel consumption) the three local manufacturers are in the bottom four in terms of performance among the 15 highest selling marques in Australia.

Corporate average CO2 emissions for light vehicles (2010) in Australia

Source: Australian Department of Infrastructure and Transport (2011)

Back in 2012 I wrote about the lament of Ford employees, frustrated that they weren’t able to develop a more fuel-efficient alternative to the 4L six-cylinder old clunker they’d been making do with for several decades. However, head offices had decided to delegate Australian operations the 'parts bin' from overseas, or expected them to make do with old technology.

The position of these global car giants is entirely understandable. Why build up Australian operations when you’ve got redundant capability close to head office in the US, Japan and Europe, where there are larger markets. Plus, Asian and South American markets hold so much more promise – and they want their own car industries.

If Australia wants to build up world competitive operations in sophisticated engineered products, we can’t rely on overseas companies to make it happen for us.