A brake on Holden's death spiral

Every Australian knows that feeling of pain and fear as they pull up at the petrol pump, not knowing what the price is going to be, not knowing if they’re going to have enough change to buy the week’s groceries.

But what if the fear we’ve been experiencing with our petrol-fuelled cars is needless and that with a simple switch we could know exactly what it is going to cost every time we want to go driving?

The future of the car industry globally and the future of the Australian automotive industry is in electric vehicles – cars that are environmentally friendly and cheaper to own and fuel – which the Australian car industry refuses to produce.

Unfortunately, by handing out over $4 billion over the past decade, our government has been encouraging our car manufacturers such as GMH (General Motors Holden) to supply us with cars so costly that they inflict petrol pump pain on ordinary Australians daily.

Despite having gifted Holden $2 billion in hand-outs over the past decade, the old car manufacturer still does the rounds ‘cap in hand’ asking for even more handouts at any and every opportunity. And for our money Holden wants to just build more of the same out-of-date gas guzzling vehicles when it should be building modern electric ones.

Through its 34-year old Commodore platform (or any platform running an exclusively fossil fuel drive train), Holden is building a product that is antiquated and at least a decade out of date.

And building an outdated car means that the advantages of subsidising and hosting a car manufacturer are significantly diminished. What value is building a knowledge base and skillset for skills and knowledge that is 20 years out of date? How can sticking by 19th century technology transfer value into other sectors of the economy and breed innovation in activities that are internationally competitive when our competitors are working with 21st century know-how?

By contrast, an up-to-date car industry has opportunities for creating local knowledge in a wide range of sophisticated skill sets immensely valuable to industry in a dynamic and ever changing marketplace.

For the past decade Holden has been afflicted with a serious case of MAD (Managed Adaptive Decline), shown by its ever falling sales and production, culminating in revenue well below what’s profitable.

Instead of looking at the fundamental cause of the problem, a number of band-aids have been applied to stem the flow, of what amounts to a ‘gusher’ of a war wound.

The bandaids, pitiful attempts including taxpayer subsidies to fix the same old problem over and over by doing tomorrow what they did yesterday, cutting workforce numbers again and again, and now the latest gambit by managing director Mike Devereux is to cut existing workers’ salaries and entitlements, as reported in The Age last week.

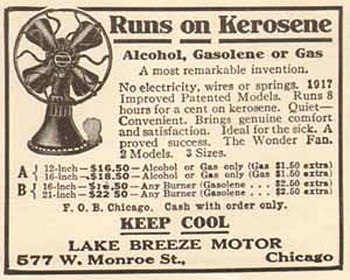

In the 1920s the gas industry was trying to get us to buy ‘all gas homes’ with crazy gas appliances like the gas clothes iron, washing machine and even a cooling fan as a last ditch desperate effort to stave off the inevitable wholesale market switch to electricity.

But when a superior energy source – electricity – came along, gas was flicked away for something more versatile, less wasteful, cheaper and safer.

Today, gas isn’t the only dirty industry gasping for life. The car industry is suffering a similar fate, teetering on the edge of collapse.

The difference between the future of the fossil gas industry and the car industry is that the latter can still change direction with two modern products that 21st century consumers will soon demand: ‘pure electric’ or ‘plug-in hybrid electric’ vehicles that don’t cost the earth to run.

The Labor government, Abbott-led Opposition and the Independents must not back another dollar going the way of these car manufacturers until they commit to retooling electric.

In the case of General Motors, it would mean that Detroit would agree to an equity stake being taken in the local operation akin to the Obama auto bailout of 2009, a case in which the government agreed to subsidise US car companies provided they produced more efficient electrical cars.

Australia’s commitment to General Motors would be conditional on the local operation having full intellectual property rights to the GM Volt platform, allowing for local research and development and a return to the local business and/or Australian people for any local innovation that makes it back into the American version of the car.

Zero Emissions, the organisation that I represent, is calling for a special action plan.

Under the plan the government sets up a fund to retool the Australian automotive industry to build pure 'plug-in electric' or 'plug-in hybrid electric' vehicles. The government offers an amount in the order of an upfront $8,000 subsidy to buyers on the first 10,000 electric vehicles produced in each Australian car manufacturing plant. This can then be followed by a lower subsidy for the next 10,000 vehicles and so on.

There is no advantage building a Hybrid here as Toyota is doing, that’s the late 90s, nor is there any point in further funding a product such as Holden’s V8 that turns off 4 of its cylinders at a time making a slight different to fuel consumption. We need to move on to vehicles that are powered at the plug and can be powered with renewables.

The Australian automotive industry needs a revolution and that involves moving each of the car manufacturers platforms from old petrol drive trains to simpler, more elegant and efficient electric drive trains.

By electrifying the Australian fleet, the bulk of which will occur over 10 years, we can beat fuel prices rises and avoid the pain at the petrol pump that is hurting so many Australians – instead running our cars on safe renewable solar and wind power.

And the price? Just under $40,000 for the US version.

In March GM said the 2014 version would be $10,000 cheaper. For comparison, the average Tasmanian government car cost $58,000.

There is an opportunity to make all Australian government fleet and other cars that are sold with subsidy, such as preferential tax treatment, electric and in doing so drive the Australian car industry to success.

Come on Holden, come on AMWU, come on Canberra, come on Aussie – let’s give Aussie workers a fair go, give Aussie workers electric vehicles to build.

Matthew Wright is Executive Director at Zero Emissions Australia.